Hydroxypropyl Methylcellulose (HPMC)

Product overview

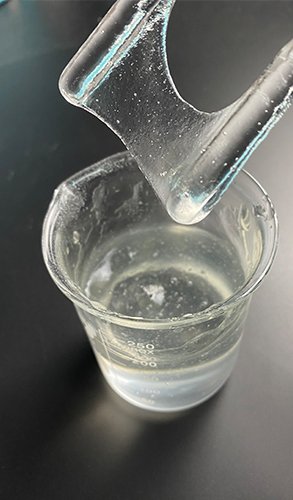

MikaZone™ Hydroxypropyl Methyl Cellulose (HPMC) is a non-ionic cellulose ether made from natural polymer material cellulose through a series of etherification. It is a white powder that swells in cold water into a clear or slightly turbid colloidal solution. It has the characteristics of thickening, dispersion, emulsification, film formation, suspension, adsorption, surface activity, moisture retention and protective colloid.

Features / 01

Thickening Effect

MikaZone™ Hydroxypropyl Methyl Cellulose (HPMC) is used very often as a thickener in building applications as it prevents segregation and improves the cohesion of the formulation components. In dry mix mortar, the thickening power is related to their solution viscosity. The addition of MikaZone™ HPMC imparts excellent stickiness to wet mortar. That can significantly increase the adhesion of wet mortar to the base layer and improve the sag resistance of the mortar.

Features / 02

Water Rentention

MikaZone™ Hydroxypropyl Methyl Cellulose (HPMC) can effectively prevent too fast and low penetration of water into the base surface in cement-based products, allowing more water to stay in the mortar and participate in the cement hydration reaction. MikaZone™ HPMC has a stable water retention capacity in a wide temperature range, although changes in ambient temperature will affect its water retention capacity. Some special grades of products can still work well in high-temperature environments. In gypsum-based and ash-calcium-based products, MikaZone™ cellulose ethers also play an important role in ensuring their open time and strength development.

Features / 03

Anti-sagging Ability

MikaZone™ cellulose ether products are suitable for a variety of construction mortars.

MikaZone™ Hydroxypropyl Methyl Cellulose (HPMC) can significantly increase the thixotropic properties of the mortar system, which allows the mortar with excellent anti-sagging ability, thereby improving construction efficiency, especially when building on walls. The good sag resistance of the mortar means that there will be no slippage when the mortar is constructed with a considerable thickness; for the tile pasting project, it means that the tiles pasted to the wall will not be displaced due to gravity.

Application

Tile Adhesive

1 Good water retention: it can prolonged opening time , to make tiling more efficient

2 Improved adhesion and sliding resistance especially for heavy tiles

3 Better work-ability: lubricity and plasticity of plaster is ensured, mortar can be applied easier and quicker

Cement Based Plaster

1 Easy dry mix formulation due to cold water solubility: lump formation can be easily avoided, ideal for heavy tiles.

2 Good water retention: prevention of fluid loss to the substrates, the appropriate water content is kept in mixture which guarantees longer concreting time

3 Increased water demand: increased open time, expanded spry area and more economical formulation

4 Easier spreading and improved sagging resistance due to improved consistency

Self-leveling

1 Protection from water exudation and material sedimentation

2 No effect on slurry fluidity with low viscosity HPMC, while its water retention characteristics improve the finish performance on the surface.

Crack Filler

1 Better workability: proper thickness and plasticity

2 Water retention ensures prolonged work time

3 Sag resistance: improved mortar bonding ability

Gypsum Based Plaster

1 Water retention: maximized water content in slurry ensures complete gypsum concretion.

2 Anti-sagging: when spreading a thicker coat corrugation can be avoided ( careful when air is entrained )

3 Increased mortar yield: depending on the weight of the dry mixture and appropriate formulation HPMC can increase the mortar

Ceramic Extrusion

1 Excellent workability for ceramic molding due to lubricity and plasticity

2 Compact texture and smooth surface of ceramic product due to negligible ash content

Exterior Heat Insulation System ( EIFS )

1 Improved adhesion

2 Good wetting ability for EPS board and substrate

3 Reduced air entrainment and water uptake.

Contact Us & Get Free Samples

Emergency? Call Us:

Send Us Mail

Have Questions?

Please fill out the form on the right to receive more detailed information from us.